Goods and services

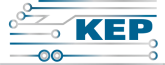

Р80 point machine

Alstom’s P80 point machine is designed to operate with minimal need of periodic maintenance while providing the highest level of safety. P80 is suitable for mainlines, metro and freight line applications.

Download PDF – eng. P80

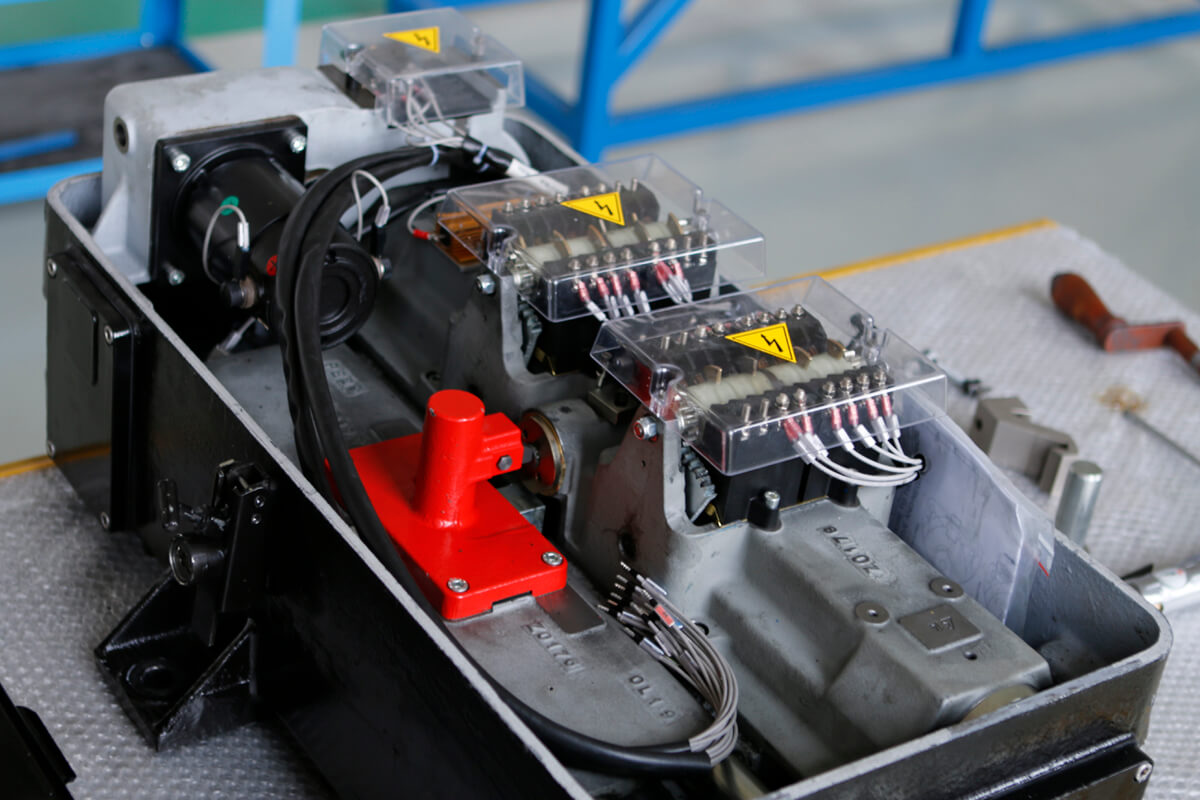

Machining

KEP provides services for the following types of machining:

• Turning

• Mining and drilling

• Boring

• Gear-shaping

• Screw-cutting

• Bandsaw cutting

• Heat treatment with high frequency currents

• Electric erosions

The machinery park of the plant includes such equipment as:

• 3 CNC mills

• 2 CNC turning machines

• 2 universal metal-cutting machines (milling and turning)

• 1 electric erosion machine

• 1 band saw

• 1 two-axis induction heat treatment machine

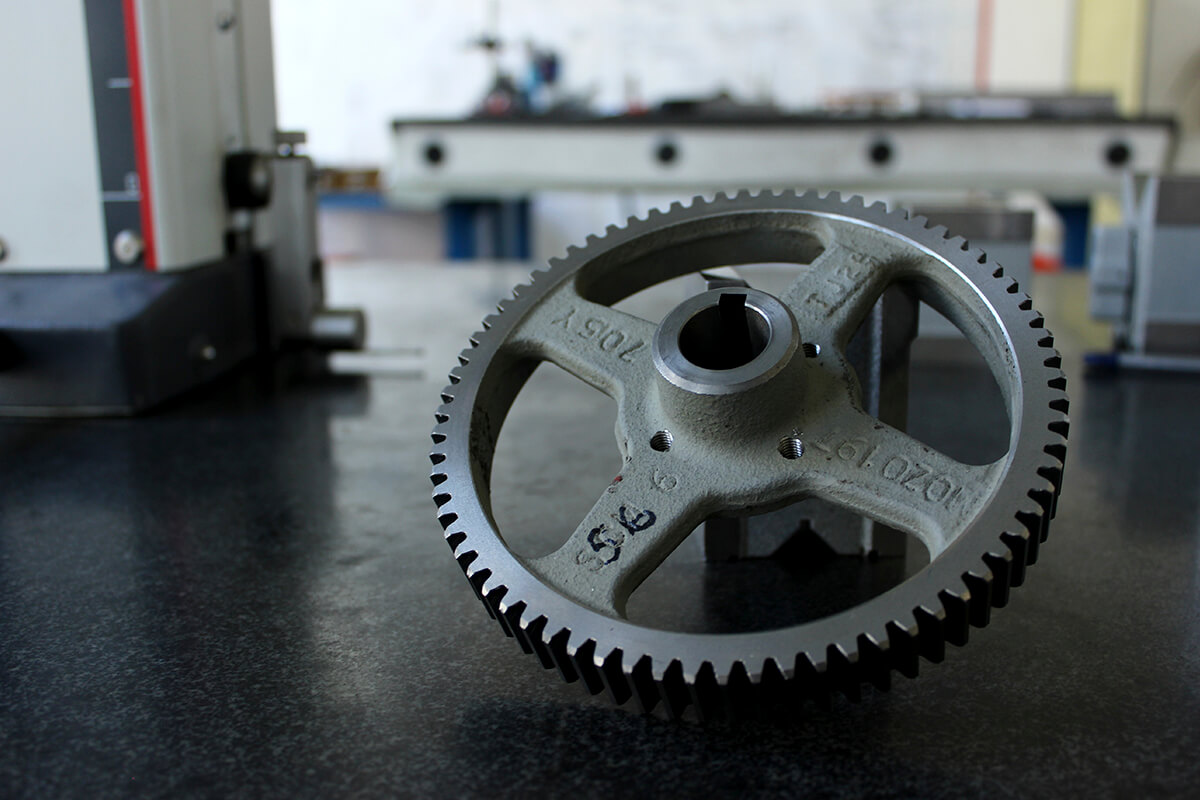

Assembly of products and components of any complexity

Experts working in the assembly section, which includes subassembly area, assembly line, test area (mechanical, electrical stands) and packaging area, can assemble products and components of any complexity.

Marking surfaces of metals and hard plastics (dot-pinning)

The PEQD-025 dot-pinning marking machine allows you to seamlessly apply clear markings on various metal / non-metal tags and parts. The content of the mark is easy to edit. Any letters, images, names, logos can be depicted on it. We carry out marking on any surface of all types of metals and hard plastics, including stainless steel, plate, low carbon steel, iron, aluminum, copper, brass, etc.

Induction heat treatment

High-intensity hardening in a two-coordinate induction hardening unit with a control unit with high specific power and short-time heating allows hardening without water cooling of the required steel grades. With this method of hardening at a frequency of 66 kHz, the required depth of the hardened layer is provided, tensile stresses on the surface do not occur, the likelihood of cracking is reduced, and low-temperature tempering is not required.

3d measurement

GLOBAL Advantage is a coordinate measuring machine, which provides the highest accuracy, dynamic characteristics and performance. The performance of this CMM was ensured by deep modernization, including the use of optimized motion algorithms, more advanced software and the use of a new electronic controller.

Advantages:

• High accuracy and excellent dynamic performance;

• Highest scanning performance;

• Multi-probe technology provides support for a wide variety of applications: from point-to-point measurements to most types of critical contact and non-contact scanning measurements;

• The use of the CLIMA standard temperature compensation system in all GLOBAL Advantage machines guarantees high accuracy even in the temperature range from 16 ° C to 26 ° C.